When it comes to choosing wood for a cutting board, it can be tempting to think ‘the tougher the better’. So, it comes as no surprise that Olive wood, (a wood so tough it’s used for hardwood flooring), crops up as a potential choice for chopping block lumber.

Now, you’re probably already aware that this trees fruits are used as an ingredient in cuisines around the world. Yet, what you may not know, is that this trees lumber can also be found in the kitchen in the form of bowls, spoons, and spatulas.

But, how does Olive wood stack up as a food safe cutting board?

Well, in this post, you will discover why almost all types of wood (including Olive wood) are antibacterial. And you will also learn why Olive woods texture makes it one of the more hygienic wooden surfaces.

And we reveal why Olive woods tough advantage is actually a disadvantage, when it comes to cutting boards.

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

What Are The Best Cutting Boards Made Of?

Solid natural wood is by far the best material for making cutting boards. And this is because, (unlike rubber or plastic), wood is actively antibacterial.

The ability for wood to soak up water and moisture with ease, also means that it soaks up liquids and juices. This draws raw meat juices down from the surface of a cutting board, right into the grain.

Which means that bacteria does not get a chance to grow in those juices.

And What Type Of Wood Is Best For Cutting Boards?

OK, so we’ve established that wood is naturally antibacterial. Still, just because wood can draw liquids away from the surface, doesn’t mean that all wooden surfaces are hygienic.

Open-pored woods, (such as Red Oak), have visibly large pores. Those big pores make it easy for tiny bits of gristle to get snagged up in them.

And once food gets lodged in pores, it can be hard to wash out those food bits afterwards.

So, for food hygiene purposes, avoid using any kind of open pored lumber for a cutting board. Especially if you’re making a face-grained chopping block.

Is Olive Wood Antibacterial And Hygienic Enough For a Chopping Block?

Olive wood can soak up water as well as any lumber, so it will work well as an antibacterial surface.

And it has tight fine grain, leaving little room for food to get caught in. So, based on hygiene, it can work well as a food prep surface.

But, there’s more to cutting board food safety, than the type of wood grain.

Wait a Minute… Isn’t Olive Wood Food Safe?

Once Olive wood has been completely sealed, then yes it is safe. However, without that finishing seal, the wood itself can cause allergic reactions if handled.

You see, Olive wood is classed as a sensitizer. This means that this wood can cause irritations and dermatitis, if it comes into repeated contact with skin.

The natural oils found in Olive wood are the main culprit. But allergic reactions, to naturally oil-saturated wood, is not uncommon.

Olive wood is not even the worst offender. Some other types of naturally oily lumber, such as Teak wood, can create more severe allergic reactions.

But, What Does This All Mean For Food Safety?

Not much, provided this wood has been properly finished and sealed.

Related Post: Don’t Use Tung Oil On Your Cutting Board (Use This Instead)

Plus, it’s very unlikely that chopping onto this tightly dense hardwood will splinter it either. So that removes the risk of raw Olive wood bits getting into your food.

However, Olive woods toughness does pose a different problem when it comes to it’s suitability as a chopping block.

Is Olive Wood Good For Chopping Boards? Or Is It Too Hard?

When it comes to judging the strength of lumber, we use something called the Janka Hardness Scale.

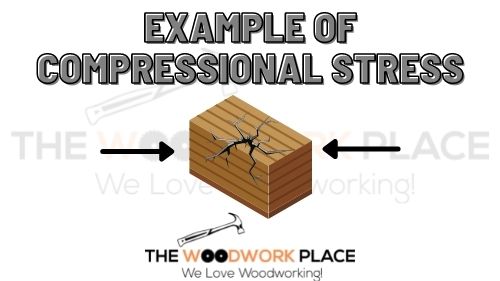

This scale measures how well wood can resist any compressional stresses put on it.

Or, to put it simply, the Janka scale measures how much force (lbf) it takes to crack a piece of lumber. The higher the Janka Rating of wood on the Janka Hardness Scale, the harder that piece of wood is.

And Why Does The Janka Rating Of Olive Wood Matter?

Well, the optimal Janka rating of cutting board wood, falls within a pretty tight range. Cutting boards should ideally have a rating between 900 lbf and 1500 lbf.

The reasons for this are simple. If it takes less than 900 pounds of force to crack the surface of a cutting board, then the board is too soft to last long.

Yet, if it takes more than 1500 pounds of force to dent the board, then it is too hard for your chopping kitchen utensils. And that board will likely end up blunting (or even damaging) your utensils.

Now, Olive wood sits well outside the optimal Janka range, with a rating of 2700 lbf. That means it takes 2700 pounds of force to dent this hard-as-nails timber.

Which also means that Olive wood will put pay to your kitchen utensils in no time at all.

To Wrap Up, Here Are The 3 Key Takeaways From This Post…

- 1). Cutting boards made from tight-grain wood are the most antibacterial and food hygienic.

- 2). Cutting boards made from very hard lumber, will blunt and damage your kitchen utensils.

- 3). Olive wood is much too hard to be used as cutting board material.

References:

Hausen, Björn M., and Hans W. Rothenborg. “Allergic contact dermatitis caused by olive wood jewelry.” Archives of Dermatology 117.11 (1981): 732-734.