Floors need to be able to handle a lot of day-to-day pressure. And that’s not to mention the increased moisture, (and potential water-damage), that can occur around sub-flooring.

So, when it comes to Plywood and Chipboard, which one of these two engineered woods is best suited for flooring?

Well, in this post you will learn the key difference between these two engineered woods. You’ll also find out why Plywoods high strength-to-weight ratio makes it ideal flooring material.

And keep reading to discover the main reason why Chipboard is sometimes used for flooring and underlayment.

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

What’s The Difference Between Plywood And Chipboard?

Chipboard, (also known as Particle Board), is made up of…yes you guessed it…wood chips.

To be more specific, it is a wood composite material of wood chips and sawdust. And they are compacted and bound together using adhesives.

Plywood, on the other hand, is made up of multiple cross-layered wood veneers.

These layers — also referred to as plies — are placed one on top of the other. And each layer is bound to each other using adhesives as well.

The cross layering effect really reinforces Plywood. And it gives this engineered material an incredible strength to weight ratio.

Is Chip Board More Water Resistant Than Plywood?

First off, neither one of these two wood composites are very water resistant. They will need to be sealed with a water-resistant wood sealer if they’re to be used outside.

However, in terms of relative water-resistance, Chipboard is much less water-resistant than plywood.

The makeup of Chipboard means that all of those extra compressed wood chips can swell if water or moisture gets into it. That swelling can cause Chipboard to bow out of place.

Worse still, it also makes this material really difficult to fix afterwards, once it becomes damaged by water.

Still, that doesn’t mean plywood is much better in this regard.

Plywood is also not very water-resistant. And even exterior graded plywood will need a sealant.

Related Post: Can You Use RTD Plywood For Roof Sheathing?

That’s because that ‘exterior’ grade refers to the type of adhesive used in this Plywood. It does not refer to the plies themselves being made of waterproof material.

Nevertheless, compared to Chipboard, Plywood doesn’t absorb any where near as much water. So, it doesn’t swell or bow out of place anything like Chipboard can.

Which One Is Heavier? Plywood Or Chipboard? Plywood is much lighter than Chipboard. Plywood is also easier to work with and machine. Chipboard, especially the highest-density Chipboard grades, are fairly hefty when compared against Plywood.

So Which One Is Stronger Over All? How Does Plywood Vs Chipboard Compare In Strength?

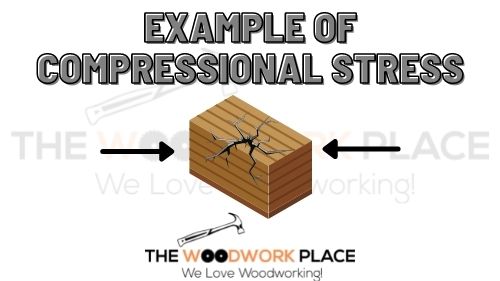

There are three main ways we can measure the strength of manufactured wood; tensile strength, shear strength, and compressional strength.

And the type of strength you need to focus on will depend on the project.

OK. So Which One’s Better For Flooring? Plywood Or Chipboard…

When it comes to floors, we’ll want to focus on the compressional strength of a material. That is because compressional strength measures how well a material can hold up when compressional stress gets placed on it.

Basically, compressional strength measures how well a material can hold up when it is being crushed. And that’s handy to look at when it comes to flooring, since we’ll be walking around on it all day.

Now, when it comes to Plywood, this material is ideal for flooring. Plywood can handle up to an incredible 5000 lbs of pressure per square inch (PSI).

Which is why Plywood is a favorite choice for making shed flooring and van floors too.

Related Post: Should You Make Your Shed Floor From Plywood Or OSB?

Chipboard, on the other hand, doesn’t quite have the same amount of compressional strength.

Mid-grade Chipboard can handle upwards of 2100 lbs of pressure per square inch. That is no mean feat — but it simply doesn’t compare to Plywood.

And that doesn’t even take into account the fact that Plywood is a more rigid material too.

This means that Plywood is less likely to sag in the middle, compared to Chipboard. Which is another plus mark in favor of Plywood over Chipboard, for flooring.

So Why Use Chipboard For Flooring? What Is Chipboard Best Used For?

Honestly? Chipboard is simply a cost-cutting material choice. You will save a fair amount of money by opting to use Chipboard over Plywood.

If you want to save money having a kitchen cabinet installed, or some flooring done, then Chipboard is an option.

But, in terms of durability, water-resistance, and maintenance, Chipboard is a worse choice for flooring than Plywood.

Even the highest graded Chipboard materials can still become fairly water-damaged.

Related Post: What You Need To Know About Sealing A Particle Board Countertop

You see, the most expensive highest-density chipboard material is created by packing more wood shavings into each board. This not only makes Chipboard denser, it also makes it stronger, less water-absorbent, and more stable.

This is the type of chipboard you should be considering if you plan on using it for flooring or underlayment. Still, this grade of Chipboard is expensive enough that any cost savings in using it (over Plywood) get canceled out.

What’s Cheaper…Plywood Or Particle Board (AKA Chipboard)? Particle board is generally cheaper than Plywood (other than specially manufactured grades). And Particle Board is a mere fraction of the cost of natural solid wood.

To Wrap Up, Here Are The 3 Key Takeaways From This Post…

- 1). Plywood has more compressional strength than Chipboard, making it better suited to becoming flooring material.

- 2). Chipboard is much more water-absorbent than Plywood. It is also more difficult to repair water-damaged Chipboard.

- 3). Chipboard is a cost-effective material for flooring and underlayment. However, Plywood is a more durable and stable flooring material.

References:

Choosing Between Oriented Strandboard And Plywood | University of Massachusetts Amherst

Strength Properties of Wood for Practical Applications | Oklahoma State University (okstate.edu)

Pędzik M, Auriga R, Kristak L, Antov P, Rogoziński T. Physical and Mechanical Properties of Particleboard Produced with Addition of Walnut (Juglans regia L.) Wood Residues. Materials (Basel). 2022 Feb 9;15(4):1280. doi: 10.3390/ma15041280. PMID: 35207821; PMCID: PMC8880566.