As a quick woodworking project, making a cutting board is an excellent way to begin learning your craft. Especially as making your own homemade chopping block is a great way to get a hang of the basics.

But, if that cutting board is going to be used for more than just decoration, you need to be careful of the type of wood you make it from.

Take Oak wood, for example. It’s affordable, plentiful, and easily accessible. You probably even have a few boards of it in your workshop right now.

However, is it suitably safe enough to make a cutting board with?

Well, in this post, you will learn why wood is such a naturally antibacterial material. You will also find out why certain types of wood are not food hygienic…in spite of their antibacterial advantages.

And we reveal the exact type of Oak wood that can be used to make any kind of cutting board…and why.

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

What Type Of Cutting Board Wood Is The Most Hygienic?

Well, first off, wood itself is already an antibacterial surface. Which makes it one of the most food-safe cutting board materials.

That’s because wood can draw raw meat juices and liquids, right down into its grain. This prevents bacteria from thriving on the surface of this food-prepping utensil.

However, while wood as a material is antibacterial by nature, not all wooden surfaces are ideal for food prepping. You see, any wood that has open-grain can be a food-safety risk.

Open-grained wood have very large pores, pores that are big enough to be easily visible to the naked eye.

And those open-pores mean that when you chop food, little bits of that food can get snagged in those pores. This is kind of like getting little bits of food caught in-between your teeth.

These open-pored wooden surfaces are tough to properly clean… especially if raw meat bits get caught up in them.

So, close-pored wood types are the most hygienic type of wood you can use for a cutting board. And you should avoid using open-pored wood.

Related Post: Acacia Vs Maple Cutting Boards (4 Key Pros And Cons)

Is Oak OK To Use For A Cutting Board?

As long as you are using White Oak wood, then Oak can be used for a cutting board.

You see, Red Oak has wide open-pored grain, making it wholly unsuitable for any kind of face-grained (or edge-grained) cutting board. Although, an argument can be made for using Red Oak to make an end-grained cutting board.

White Oak, on the other hand, also has open pores. However, with one caveat; it’s pores have been naturally sealed thanks to cell growths called Tyloses.

Tyloses make White Oak more water resistant than Red Oak, by damming up White Oaks water-wicking pores. And these Tyloses outgrowths will also prevent food from getting snagged up in White Oaks pores.

What’s more, those Tyloses also help prevent White Oak from rotting away quickly too. In fact, if you used unfinished White Oak for, say, building a fence outside, it would hold up for up to 20 years without any extra treatment.

Of course those Oak posts might start leaning a bit after a decade or so. But still, getting 15-20 good years out of untreated oak lumber is pretty impressive! Making White Oak one of the most naturally rot-resistant woods you can use.

We’ve got more details on using it for fence posts over here if you’re interested in learning more: Is Oak Wood A Good Choice For Fence Posts?

So, White Oak wood can be used to make face grain, edge grain, or end grain cutting boards.

Related Post: Edge Grain vs Face Grain Cutting Boards (Which Is Which?)

What’s The Difference Between Face, Edge, And End Grained Cutting Boards?

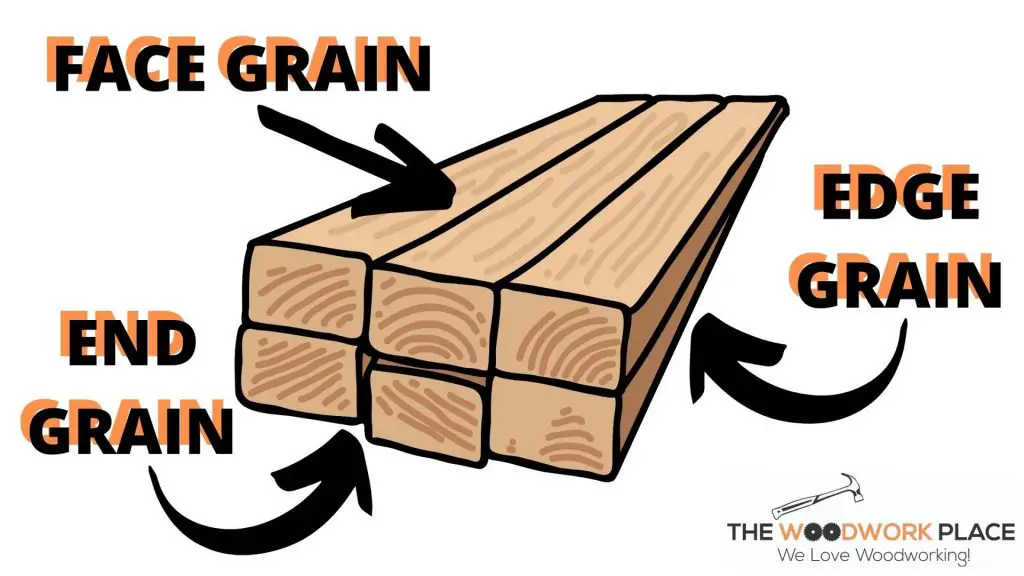

Any wooden board, (provided it has been planed at the lumber yard), has three sides. Wooden boards have a ‘Face’, an ‘Edge’ and an ‘End’ side to their grain.

A Face grain cutting board has the face grain visible as the food prepping surface of the board. Edge grain boards have the edge side of the wooden board visible.

And end grain cutting boards show off the extreme ends of a wooden board.

So, Is Oak Good For Making End Grain Cutting Boards?

White Oak is perfect for an end grained cutting board. Red Oak, on the other hand is a bit of a mixed bag.

Wood pore snagging is less of a concern when it comes to dealing with end grain surfaces. So, using Red Oak for this particular type of board shouldn’t be an issue either. But, it’s up to you.

Regardless, White Oak and Red Oak have Janka ratings between 1290 lbf and 1360 lbf.

Which is why White Oak is so hard to work with or carve into using manual tools. With its high Janka rating, you’ll need some really sturdy tools to make your way through that tough lumber.

That’s why oak works so well for wood carving techniques that require hard, durable wood, such as chainsaw carving. It can stand up to the chainsaw blades much better than lower rated hardwoods.

So if you’re looking to do some wood carving, white oak is a great choice for anything involving power tools or rougher carving methods. The hardness makes it ideal for that. We’ve got more details on carving white oak over here if you want to learn more about using it for chainsaw art and other tough carving techniques: Is Oak Wood A Good Choice For Chainsaw Carving?

But, either way, at the end of the day, both types of Oak are plenty both strong enough to be made into a heavy duty end grain chopping block.

And What Exactly Is This Janka Rating?

It is a measurement that indicates how many pounds of force it’d take to dent any given piece of wood.

The higher the rating, the more pounds of force (denoted by ‘lbf’), it takes to make a dent in a piece of lumber.

Why Does The Janka Rating Even Matter For Cutting Boards?

Wood needs to be tough enough to handle metal blades. And yet it needs to be ‘soft’ enough to not end up dulling those self-same blades.

That is why the optimal Janka rating, for cutting board wood, is between 900 lbf and 1500 lbf.

To Wrap Up, Here Are The 3 Key Takeaways From This Post…

- 1). For food hygiene purposes, avoid using open-pored wood to make a cutting board. That’s because food bits can get snagged in those pores.

- 2). Red Oak wood has open-pored grain, so this particular type of oak is unsuitable for a cutting board.

- 3). However, White Oaks open-pores have been naturally ‘sealed’. So, you can use this type of oak wood for a cutting board.