Natural solid hardwood is one of the best materials you can use to make a trailer deck. But wood strength doesn’t count for much when it comes to decay.

Plenty of otherwise tough strong hardwoods can quickly succumb to rot if they’re left outside in the elements. However, one way we can protect timber from rot, is to treat it with wood preservatives.

But, what does pressure treated wood actually do to lumber? And does your wooden trailer deck really need it?

Well, in this post, you’ll will find out what type of material is ideal for trailer decking. You’ll also learn why pressure treatments increase the durability of wood — and whether or not a trailer deck needs treating in the first place.

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

What Type Of Wood Is Best Suited For A Trailer Floor?

Any material used for a trailer floor needs to be strong and water-resistant. Which is why Phenolic Plywood, (a manufactured wood), is ideal for a utility trailer floor.

Phenolic Plywood is made from Baltic Birch, (also known as European Birch). But, what makes Baltic Birch plywood so strong is the fact that it has 13 ply layers to it. On the other hand, your standard plywood only has 5-7 plies.

What’s more, the glue used to keep those plies together is made from a water-resistant glue. So this particular plywood is less likely to fall apart due to moisture or outdoor humidity.

Related Post: What’s The Best Type Of Wood For A Utility Trailer Floor?

What About Natural Solid Wood? What’s The Best Type Of Solid Wood For A Trailer Deck?

If you want to make a trailer deck, then your best (and most affordable) option is to use White Oak.

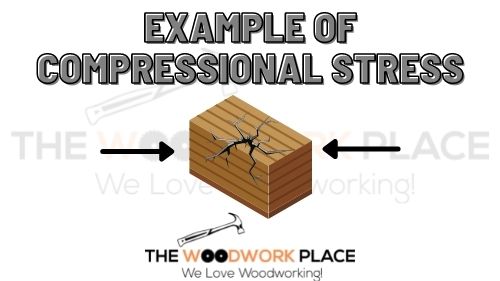

This hardwood has natural characteristics that make it rot-resistant. And this lumber can take on incredible amounts of compressional stress — all without collapsing in on itself.

That is why White Oak is popularly used for making trailer decks. In fact, there is a specific term for the type of Oak used in this way; Rough Oak.

And Why Exactly Is It Called Rough Oak? What’s So Special About It?

Rough Oak is simply natural raw roughly cut White Oak wood that has been sawed into planks.

Rough Oak is also left completely untreated. So, it has not been heat-treated, kiln-dried, or pressure-treated with wood preserving chemicals.

Related Post: Are Heat Treated Pallets Really Safe Enough For Gardening?

What About Red Oak? Is Red Oak Also Good For Trailer Decking?

Red Oak is about as tough and as hard as White Oak. But, it does not have the water-resistant characteristics of White Oak.

You see, White Oak has these extra cell growths that form over the pores of this particular Oak subspecies. These cell growths are called Tyloses, and they act like a natures-own stopper, preventing moisture from soaking into wood.

Red Oak, on the other hand, does not have Tyloses. So, while White Oak has superb rot-resistance, Red Oak does not.

How Long Does Untreated Rough Oak Wood Last For? If it has direct ground contact, it will last about 10 years. But, if it is kept off the ground, it can last for over 20 years.

What About Treated Oak? Will Pressure Treated Oak Wood Last Longer?

Absolutely it will, and here’s why…

Pressure treated wood has been put through a process that involves infusing wood with water-soluble wood preservatives. And those wood preservatives have one job; they are there to fight off any bacteria responsible for wood rot.

Now, Rough Oak wood can still last a good while without those wood preservatives. But, pressure treated Oak wood will last even longer.

To Wrap Up, Here Are The 3 Key Takeaways From This Post…

- 1). The best type of material for a trailer deck is Phenolic Plywood, or Rough White Oak.

- 2). White Oak is tough, durable, and rot-resistant. If kept off the ground, untreated White Oak can last up to twenty years without succumbing to decay.

- 3). However, pressure treated White Oak will last even longer. That is because pressure treated White Oak has been infused with rot-resisting wood preservatives.