A utility trailer is only as strong as the materials used to make it.

If you have a trailer floor made from wood that isn’t strong enough to carry heavy loads—or water-resistant enough to handle the weather—then you don’t actually have a utility trailer.

Instead, what you’ll have is an accident waiting to happen.

So, in this post, you’ll learn what type of wood (both engineered and natural) are ideal for utility trailers. We also explain why these specific wood types are so well suited for flooring.

And you will also discover why a certain popular composite wood material, just isn’t durable enough for a trailer.

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

What Type Of Wood Is Best For A Trailer Floor?

The best type of wood for any trailer needs to be both water-resistant and strong. It also needs to be stable too (which means it won’t warp and twist if moisture gets into it).

As a result, engineered wood types, are consistently the most ideal material for a utility trailer floor.

That is why Phenolic Plywood made from Baltic Birch wood is the best, (albeit pricey), option timber for a trailer floor. This plywood is perfect for a utility trailer for two good reasons.

Related Post: What Is The Best Plywood For Outdoor Use? (Solved!)

Phenolic Boards Are Moisture Resistant

Phenolic boards refers to plywood that has been manufactured using a special type of adhesive made from phenol-formaldehyde resin.

This glue is really good at resisting moisture. And this in turn, makes this plywood less likely to delaminate. Which is why phenol-formaldehyde based glue is popularly used to bind the veneers of exterior graded plywood.

What Is Delamination? This refers to what happens when moisture gets into the glue of plywood. That moisture weakens the glue, causing those individual plies to fall apart.

Baltic Birch Plywood Is Warp Resistant

Baltic birch, (sometimes referred to as European Birch), is a straight-grained hardwood sourced from Finland (mostly), Latvia, and Lithuania.

Baltic Birch wood itself isn’t naturally rot-resistant (unlike Douglas Fir, which is fairly good at fighting off rot).

Birch wood may not be as tough as say Hard Maple, but it’s still pretty durable. You’d need to really go at it to make a deep scratch in this North American hardwood.

Now, Birch is definitely an affordable choice if you’re looking for interior furniture like counter-tops. However, it’s not the most decay-resistant option out there, especially if you’re putting it in a high-moisture area like the kitchen. Especially since Birch can be a bit prone to water damage.

If you want the nitty gritty on using birch for counter-tops, check out our post comparing it to rubberwood here: A Quick Beginners Guide To Rubberwood Vs Birch Wood [For A Butcher Block Countertop]

We really dive into the pros and cons for each wood when it comes to kitchen counters – durability, moisture resistance, cost, etc. The info will help you decide if birch is the right material for your needs or if you’d be better off going with something like rubberwood.

Instead, what makes Baltic Birch Plywood so warp resistant is in the way it is manufactured.

Baltic Birch Plywood has 13 ply layers to it. Whereas your typical plywood sheet, will only have around 5-7 layers to it at most.

This makes Baltic Birch less likely to warp and twist around. Especially as all of those alternating ply layers help to keep it flat.

Phenolic Baltic Birch Is Too Pricey. What Is The Best Natural Solid Wood Timber For A Trailer Floor?

The best natural solid wood option for a trailer floor is White Oak. This timber is naturally water-resistant, and it has great strength and durability.

In fact, even without a wood sealer, White Oak can stave off wood rot and decay for years.

And there is a good reason for this… White Oak has some neat traits that make it super weatherproof.

The wood has these growths called tyloses that seal up its pores. It’s kind of like the tree is trying to survive drought or bugs by blocking up its pores so moisture can’t escape or pests can’t burrow in.

White oak also has high levels of tannins, which are natural fungicides. These compounds prevent bacteria from thriving inside the wood.

If you want to learn more on why White Oak can stand up to the elements so well, check out our post: Is White Oak Good For Making Durable Outdoor Furniture?

So You Can Use Any Oak, Even Red Oak, For Trailer Decking?

You mustn’t use Red Oak for any outdoor items. That is because Red Oak does not have the special water-resistant quality that White Oak has.

You see, White Oak wood has these unique cell growths called Tyloses. These cell growths form over the wood pores of White Oak, and act like a stopping plug. And with Tyloses plugging up its pores, White Oak doesn’t absorb water the way that Red Oak does.

Red Oak, on the other hand, does not have any Tyloses, so it is vulnerable to water damage. So, you can use White Oak for the utility trailer floor… but steer clear of Red Oak.

Related Post: Is Oak Wood A Good Choice For Fence Posts?

Can I Use OSB For A Trailer Floor Too?

OSB (Oriented Strand Board) is a manufactured wood, just like plywood. However, the texture of this material makes it unsuited for a trailer floor for two good reasons;

1 ). OSB Is Less Moisture-Resistant Than Plywood

Comprised of compressed wood chips, each sheet of OSB is primed for absorbing water. As a result, OSB doesn’t handle humid conditions as well as Plywood.

There are certain water-resistant grades of OSB (namely OSB/4) that can handle high-humidity environments (i.e. the great outdoors). But, these high quality OSB boards cost an absolute arm and a leg, and are much more costly than plywood.

2 ). OSB Isn’t As Strong As Plywood (When It Comes To Flooring)

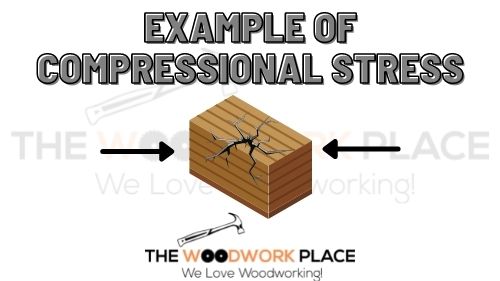

When it comes to compressional strength, OSB is only half as strong as Plywood.

Compressional strength measures how much compressional stress you can place on a piece of wood, before it cracks. Or, to put it another way, compressional strength measures how much weight a wooden board can ultimately take.

Plywood, (depending on the type), can take anywhere from 3000 to 5,000 pounds of pressure per square inch. While, OSB can only take around 1500 to 2500 pounds of pressure per square inch.

So, if you plan on ferrying heavy loads in your utility trailer, Plywood is better suited for it than OSB.

To Wrap Up, Here Are The 3 Key Takeaways From This Post…

- 1). The best type of manufactured wood, for a utility trailer floor, is Phenolic Baltic Birch Plywood. Between this plywood’s added extra layers, and its moisture-resistant adhesive, it makes for durable flooring material.

- 2). The best type of natural solid wood, for a utility trailer, is White Oak. This strong tough hardwood is naturally rot-resistant.

- 3). But, don’t use Red Oak wood, as this particular subspecies of Oak is not suited for the outdoors.

References:

Choosing Between Oriented Stand Board And Plywood | UMass Amherst | Department of Environmental Conservation

Phenol formaldehyde resin | Wikipedia.org