They may not have as much shear strength as your typical nail, but screws are one of the best ways to hold wood boards in place.

But what happens when a screw simply won’t fasten properly? And what should you do when a screw won’t go all the way into wood?

If the screw turns freely, but is not fixing into the wood, then the problem could be that the screwdriver doesn’t fit the screw head correctly. Another issue could be with the type of screw you’re turning. For example, slotted head screws don’t offer enough contact points for a screwdriver to grip onto.

But surely there must be a bit more to it all than this, right? Well, keep reading to find out exactly why that screw is giving you trouble (and how to quickly fix it!).

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

Why Won’t My Screws Go All The Way In?

There are a wide range of reasons why a screw suddenly won’t do its job properly. But, here are the 5 most common reasons as to why a screw won’t stay into place;

1. Stripped Screw Head

Stripped screws are a real tricky problem. A stripped screw refers to a screw head that is so badly damaged it is incredibly difficult to turn it with a drill or a screwdriver.

Screw heads can easily become stripped if you’ve tried to fasten them using a screwdriver that is too small.

What Screw Head Is Least Likely To Strip?

If you are using the correct sized screwdriver tool and drill bits, (but keep finding yourself stripping the screw head), then it is time to look into getting better screws.

The more popular standard Slotted Head Screw tends to strip easily. So instead, opt for Phillips Head Screws for fastening wood joints.

Phillips Head Screws are screws that have non-slip screw heads. Basically, these screws are designed to help prevent stripping.

And just why are Phillips Head Screws so much better? Well, Slotted Head Screws have just 2 points of contact. The Phillips Head Screw, on the other hand, has 4 points.

These extra points of contact mean that a Phillips Head Screw has a lot more grip. All of which combines to reduce the chances of your screwdriver slipping off the screw.

And a great assortment of Phillips Head screws can be found in T.K. Excellent’s fantastic ‘Phillips Flat Head Wood Screws Kit’. There are 150 metal screws in this kit, all in the following six sizes: #6×1/2″, #6×3/4″, #8×3/4″, #8×1″, #8×1-1/4″, and #10×2″.

You can find the latest prices for these Phillips Head Screws by checking them out on Amazon.com

2. Incorrect Screwdriver Size

Sometimes there is no problem at all with the screw head, and instead the problem is with the screwdriver itself.

The size of the screwdriver (or power drill) really matters. If it is not the correct size, then you risk more than just an almighty struggle trying to turn that screw. You can also risk stripping the screw head, which can make it impossible to remove it later on.

So make sure that the screwdriver is big enough, (or small enough), to match and neatly catch the screw head. The best way to do this is to bring your screwdriver to the hardware store. That way you can measure up the hardware store screws with your particular set of tools.

Or, if you’re in the market for a brand new screwdriver, you need to check out Amartisan’s 10-Piece Magnetic Screwdrivers Set.

These cleverly designed screwdrivers have special magnetic tips that attract and draw metal screws right to them.. making it easier for you to lock in and turn.

Check out the latest prices for this magnetic screwdriver set over on Amazon.com

Why Does My Drill Keep Stripping Screws? An incorrect sized drill bit is the main culprit. An undersized drill bit on the end of a power drill can easily damage screw heads.

3. Poor Screwdriver/Drill Bit Quality

If you are using an old manual screwdriver and you are struggling to get a decent grip on the screw, then it might be time you upgrade to a new one.

Similarly, double check your power drill bit to see if it has become worn down from use.

Do You Need To Drill A Hole Before Putting A Screw In? Yes, these pre-drill holes are called Pilot Holes. Pilot holes are essential. They are there to help make it easier to guide the screw into place.

4. You Did Not Drill A Pilot Hole

A pilot hole is the hole you drill into wood before you drive the screw into lumber.

This is an important step, because without a pilot hole for the screw to enter, you risk breaking the screw as you drill.

Even worse, without those all important pilot holes, you risk creating cracks in the wood when you drill into it. And those cracks could end up weakening the very wood joints that you’re fastening into place.

5. The Pilot Hole Is Not Wide Enough

Now, a pilot hole should be (at a minimum) as big as the minor diameter of the screw. Especially when screwing into hardwood lumber.

However, if the wood you are screwing into is tough and more resistant to screws, you will need to make that pilot hole a little bit wider than its minor diameter.

And the opposite is true, if the wood is easier and softer to drill into, then the pilot hole can also be a bit smaller than the minor diameter of the screw.

What Is The Minor Diameter Of A Screw?

The minor diameter of a screw is the smallest diameter of a screw thread. In other words, it is the diameter of the extreme low end of the screw thread (i.e. the tip of the screw).

So, How Do You Fix A Screw That Won’t Tighten Wood?

There are a number of different ways you come at this problem. However, by far, the easiest and most straightforward method is to use the matchstick dowel technique.

Matchstick Dowel Hole Solution

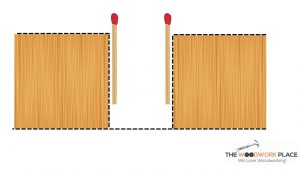

Step 1. Remove the screw from the hole.

Step 2. Find a couple of toothpicks or matchsticks.

Step 3. Coat the matchsticks with some wood glue and place them flush against the sides of the hole.

Step 4. Wait for the glue to dry.

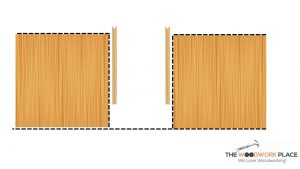

Step 5. Cut the matchsticks down so that they are level with the edge of the hole.

Step 6. Drill a pilot hole that’s about the width of the minor diameter of the screw.

Step 7. Put the screw back in and start screwing into the wood.

Final Thoughts

At the end of the day, there are a range of different sized screws, screw drivers, and drill bits.

As long as you pair your screws up with the right sized screwdriver, you’ll rarely have to deal with slips and stripping.

However, that is all provided that you do the following;

- Always Pre-Drill A Pilot Hole. These take time, but will save you a lot of hassle in the long run.

- Use Phillips Head Screws. Ditch flathead screws and opt for a screw that offers way more grip.

- Take Your Power Drill or Screwdriver To The Store. Use it to check that you’ve purchased the right-sized screws for the job.