Your shelves need to do one thing really well…and that’s not to sag under pressure. A vase, stack of books — or even a full toolbox — should pose little problem for well-made shelving.

But, more often than not, how you build your shelf isn’t the key to preventing sagging. Instead, it is the material used to make that shelf that’s more important.

So, between Plywood and MDF, which one of these two materials is least likely to slump on the job?

Well, in this post you’ll learn what compressional strength is — and why too little of it can lead to sagging shelves. You’ll also find out why Plywood thickness could make or break your DIY bookcase project.

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

Is MDF Or Plywood Better For Shelves?

While either material can be used for shelving, Plywood is the clear winner.

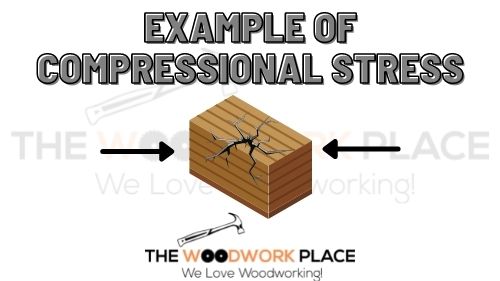

You see, one way we measure the strength of a material is by looking at it’s ‘compressional strength’.

Compressional strength measures how well wood holds up under a crushing force, or rather ‘compressional stress’.

And compressional strength is a good way to measure how well either MDF or Plywood can do as shelving. Especially since shelves will be under a fair bit of downward compressional stress, when holding up heavy objects.

Now, Plywood has amazing strength-to-weight ratio (as it relates to compressional strength). This engineered wood can hold up around 5000 pounds of pressure per square inch (PSI).

But MDF doesn’t even come close.

Instead, Medium Density Fiberboard (MDF) clocks in at around 3500 PSI. Which is a respectable amount, but still far short of Plywoods Olympiad-level numbers.

Don’t get me wrong, MDF is sturdier than a lot of cheaper manufactured woods on the market.

Take Mid-grade Chipboard – this material can withstand over 2,000 pounds per square inch before it gives. Nothing to sneeze at for sure.

But just like with MDF, chipboard is still no match for good old plywood when it comes to compressional strength. In fact, we get more into plywood vs. chipboard in another post here if you’re curious for the nitty gritty details: Plywood Vs Chipboard: Which One Has The Strength To Make For Great Flooring?

The point is, while MDF has its place, it’s just not in the same league as plywood when you really need something solid and long-lasting.

Related Post: Can You Use Polyurethane On MDF (To Protect It From Water Damage)?

But Why Does Having Great PSI Numbers Matter For My Own Shelves?

Well, it means that MDF is more likely to sag down in the middle under the heft of weighty objects. Certainly more so than Plywood.

On the other hand, Plywood is a more rigid, stable, and sturdy material than MDF.

What’s more, Plywood is less likely to become water-damaged by humidity or moisture.

Related Post: Why Is My MDF Board Warping? (+ How You Can Fix It)

Does That Mean Plywood Shelves Never Sag?

Not entirely. The possibility of sagging depends on different factors.

Everything from the thickness of ply — to the type of wood that Plywood was made from — can play a factor.

However, if you want a more precise way of knowing if your shelves will sag, then check out The Sagulator by Woodbin.

This handy free online calculator lets you work out the likelihood of your shelves sagging under any given weight.

Simply enter in a few quick details, and The Sagulator will do the rest.

You can start using The Sagulator straight away by checking it out over here: woodbin.com/calcs/sagulator/

So What Is The Best Type Of Wood Material For Shelves?

When it comes to shelving, your best bet is going with dense hardwoods that are naturally resistant to warping – we’re talking woods like white oak or black walnut.

Now, it’s worth clarifying here that black walnut can actually be pretty warp-prone depending on the source. Only old-growth black walnut that’s cut from really ancient, slowly-grown trees tends to be dense enough to avoid warping issues.

Those centuries-old trees have had loads of time to develop super dense grain patterns, which is what makes their lumber so sturdy and rot-resistant. But that’s a whole other tangent – if you want the full scoop on black walnut, we’ve got a post here if you want to learn more: Is Black Walnut Good For Outdoor Furniture?

The main takeaway is, quality hardwoods like oak and walnut generally make more durable shelving than manufactured woods like plywood or MDF. The natural density gives them an advantage over those mass-produced sheets. But hey, the manufactured stuff is more affordable, so it’s got its place too. Just maybe not for heavy-duty shelving.

And What Is The Best Type Of Plywood For Storage Shelves?

For interior storage, the quality of the plywood grade is completely up to you.

Plywood grades (A, B, C, and D) refer to the quality of the boards themselves. Plywood graded A is smooth, high quality, and void-free.

Whilst D grade plywood is the lowest quality grade ply you can get.

Related Post: What Is BCX Plywood? (Everything You Need To Know)

But, when it comes to shelving, the plywood grade isn’t what matters most. Rather, it’s the thickness of that Plywood sheet that is key.

The thicker the Plywood sheet, the greater the compressional strength of the material.

And when it comes to shelves, you should opt for a minimum thickness of 3/4 inches thick. Any thinner than that, and sagging will become an ongoing problem.

So, Which One Is The Best Material To Use For Shelving?

Use Plywood. It is by far the better shelving material choice compared to MDF…and it’s not even close.

To Wrap Up, Here Are The 3 Key Takeaways From This Post…

- 1). Plywood has greater compressional strength, per square foot, than MDF.

- 2). Materials that have high compressional strength are less likely to sag.

- 3). The thicker the plywood sheet, the greater its compressional strength. Which is why you should use at least 3/4 inch thick Plywood for shelves.

References:

Comparison of results obtained by static 3- and 4-point bending and flexural vibration tests on solid wood, MDF, and 5-plywood | Degruyter.com

Strength Properties of Wood for Practical Applications | Oklahoma State University (okstate.edu)

Examine the value of MDF | Woodworking Network Magazine