Nowadays, we have so many different kinds of manufactured wood types to choose from. And whether it be Veneer, Fiberboard, or Plywood, the choice is endless.

But, to quickly sum up, Manufactured Wood is when wood receives different kinds of treatments for improvement.

Also known as ‘Engineered Wood’ or ‘Composite Wood’, it is an umbrella term used by experts for a range of different materials.

Manufactured wood is produced through the combination of different ingredients, like sawdust and glue, with the special application of heat and compression. It can also be comprised of different wood pieces or wood sheets.

Manufacturers often develop it from the same hardwoods and bind them together with adhesives or other methods of fixation. It gives them the ability to have any thickness they want according to the precise design specifications to meet national and international standards.

And if you keep reading, you’ll learn why manufacturers, carpenters, and furniture makers alike, love to use this special type of lumber…

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

Is Manufactured Wood Good? | 9 Benefits Of Manufactured Wood

- Manufactured wood is more resistant to fire.

Manufactured wood reacts differently when it burns, compared to untreated lumber.

This is due to layering in manufactured wood. The layers reduce the amount of oxygen reaching the wood, which slows down the burn process.

- You can use it for flooring; because it looks like real wood.

Even the toughest skeptics can be fooled by its appearance and believe that the floor is made of solid wood.

- The length of manufactured wood can be longer than the average length of natural lumber.

This means that it can be used for various flooring styles in interior design.

For example, it gives you a great option to work on open floor plans that often require extraordinary length. Furthermore, it is possible to use this wood for large decorative pieces too.

- You can have get it in a wide variety of wood species, colors, and finishes.

Plus, it can come in a varied range of thickness too.

- Manufactured wood doesn’t expand or contract like solid wood in regions with a diverse and rough environment.

The moisture level or the constant changes in the temperature don’t affect its quality or cause any damage.

For that reason, manufactured wood is particularly used in the kitchen and bathroom as they deal with lots of dampness.

- It is more flexible and pliable compared to other wood types.

Professional architectural designers count on them for curves, walls and other complex design projects.

- They meet almost all the building standards due to their strength and durability.

Makers of manufactured wood use heavy-duty glue that bonds the wood particles strongly together.

This gives the lumber many extraordinary features, like waterproofing quality, resistance to rot, insects, and molds, etc.

The layers and layers of plywood make it incredibly tough as well and an ideal choice for domestic and commercial buildings.

- Manufactured wood has better sustainability…

This is because lumber companies increasingly get their supplies from renewable sources of wood.

Whats more, they utilize parts of the wood that would have otherwise been burned or wasted.

- One more great benefit of manufactured wood is its top layers can be refinished if necessary.

And, a quality finish can keep lumber looking in top-notch condition for years.

Is Manufactured Wood Durable?

The durability of manufactured wood relies on the thickness of the top. If you maintain it well, it can last a lifetime.

Luckily, there 5 things you can do to keep it in good condition;

- Prevent abrasive particulates from scratching the surface as they can damage it.

- Next, if you use a vacuum cleaner, make sure it is set to the bare floor setting.

- For picking up dirt and debris, keep mopping to a minimum. Instead, use microfiber for collecting dirt and dust.

- Keep mats and rugs at entranceway’s only, as they are the key source of pebbles, dirt, moisture, and grains of sand.

- And lastly, avoid using high heeled shoes on the manufactured wood flooring, as they affect the upper layer of the floor.

Final Thoughts

There are some pieces of wood today that are the combination of solid wood and manufactured wood. This is so that buyers can get a high-quality piece of wood for a fraction of the price.

For example, office desks typically a combination of both solid wood and manufactured wood.

However, despite the vast assortment of manufactured wood types on offer, I’ll stick to listing the most commonly used varieties below;

The Different Types of Manufactured Wood

Particleboard

Particleboard, also famously known as chipboard, is composed of sawdust.

It is less dense and cheaper than other manufactured wood boards in the market.

You see this type mostly in low-end furniture because of its low-cost manufacturing.

Related Post: Can You Really Stain Particle Board? (+ How You Can Make It Look Great!)

Fiberboard

This board is made out of wood fibers and has a medium density.

Manufacturers soften the raw material by cooking them in pressurized steam and create a uniformly sized fiber.

We see this manufactured wood type in pianos and instruments.

Medium Density Fiberboard (MDF)

It also has a medium-density level, however, it is more durable and stronger than a simple fiberboard.

That’s why MDF boards are used to construct fine furniture, such as dining tables or office tables, as it makes them look sturdy.

Plywood

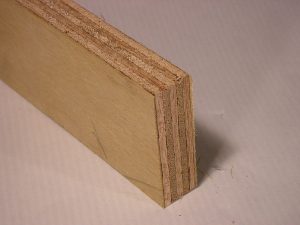

Plywood or laminated board is made from thin layers or plies of wood that are glued together.

It is mainly produced as a flat sheet for a wide range of structural, interior, and exterior applications.

It is fire resistant and also provides sound and thermal insulation.

Veneer

This is a paper-thin cut of wood that is pressed onto core panels for a variety of purposes.

This manufactured wood type is usually thinner than 1/8 of an inch. We often see it on the door and as panels for cabinets and parquet floors.