When it comes to restoring a weathered boat, the materials you use really matters.

After all, from the hull to the deck, you need to be sure that whatever you use is durable enough to take on those sea-salty elements.

Which is why a widely used material for boat repair is plywood. This densely veneered manufactured wood has a surprisingly high strength to weight ratio. Which, in short, means that it is lightweight enough to not weigh down your boat – yet is still durable enough to last.

Still, not all types of plywood are made equal. Used to make everything from outdoor roofing to indoor furniture, there are many different types of plywood available on the market.

But what kind of plywood is best for a boat floor?

The best type of plywood for boat flooring is marine grade plywood – ideally made from Douglas Fir or Western Larch wood. Marine plywood differs from regular plywood in that marine-grade plywood is made with 5 or more veneered layers glued together with waterproof adhesive. Regular plywood, on the other hand, is typically made with just 3-layers.

Related Post: What Is The Best Treatment For Douglas Fir Porch Decking?

Plus, marine-graded plywood offers more waterproofing than even exterior plywood sheets. That’s because the glue used to make marine ply is both weather and heat proof – and the sheets of this wood type are made with no voids or holes anywhere.

However, does it really matter what plywood you use? Surely, if you simply take the time to really seal regular plywood up, shouldn’t that be enough to make it watertight?

Well, keep reading as we explore a little more into the world of marine plywood and why you should use it to restore your boat…

This post may contain affiliate links to products that we receive a commission for (at no additional cost to you). Learn more here.

Do You Always Have To Use Marine-Grade Plywood On A Boat Floor?

If you are looking for a more budget-friendly option than marine-grade, then exterior grade plywood can be a good alternative.

You may sacrifice a little bit in quality, (because lets face it, marine plywood is incredibly well produced), but this alternative should still be good enough to keep out water.

So, What Can You Use Instead Of Marine Plywood?

Exterior grade ply made with waterproof adhesive is the type of plywood used on exterior constructions such as roofing. So this ply type should be more than able to handle outdoor elements.

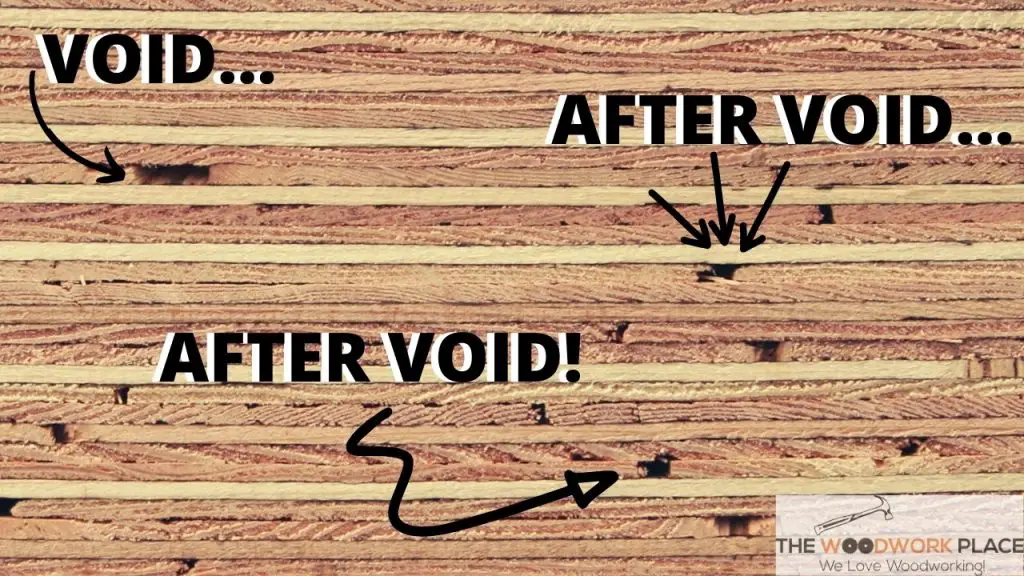

However, exterior grade ply is not exactly void-free like marine grade plywood. And it may not even come pre-sanded and smooth like marine ply does either.

So it is going to require more work from you to get exterior plywood ready for your boat flooring project. And you will need to pay particular attention to filling in any voids with wood filler.

What Are Plywood ‘Voids’? Voids in plywood are those gaping holes you find along the sides of plywood (and sometimes on the surface of the sheet).

But, Isn’t Exterior Plywood Pretty Much The Same Thing As Marine Plywood?

Well, marine grade and exterior grade plywood differ in two key areas;

- Type Of Glue

The glue used to bond marine grade ply is more water proof and it can even handle high temperatures.

- Number Of Veneers

Marine grade plywood is made by gluing five or more layers together – giving it more strength and durability. Exterior grade plywood (like its interior graded cousin) is made with three layers.

Still, that’s not to say that marine grade is the strongest of all the plywoods out there.

For example, Baltic Birch Plywood is a plywood that is arguably even stronger than marine plywood. It’s made up of 13 alternating ply layers compared to the typical 5-7 layers in most other plywood. That extra layering makes it really resistant to warping and twisting over time.

Now, natural Birch wood itself doesn’t have natural rot resistance (unlike say Teak wood for example). Instead, it’s the manufacturing process that gives Baltic Birch Plywood its strength.

But, Baltic Birch Plywood won’t stand up to saltwater like marine grade plywood can though. So if you need something that can handle the high seas, marine plywood is still the way to go.

However, for other applications, such as trailer floors, Baltic birch is a sturdy pick that will hold up well. In fact, we dive more into the topic here: What’s The Best Type Of Wood For A Utility Trailer Floor?

So, long story short, marine plywood is your best option if you want a truly long lasting plywood boat floor.

And Just How Long Will Marine Plywood Last?

It all depends on the grade of marine plywood.

Regular Interior/Exterior plywood is available in four different grades. Each grade is a mark referring to the quality of the plywood sheet.

The highest grade – Grade A – means that the plywood is smooth, sanded and ready to go.

The lowest grade – Grade D – means that the plywood is riddled with knots and imperfections. And that the plywood can have voids that are up to 2 and a half inches deep.

Now, on the other hand, marine plywood only comes in two grades; Grade A and Grade B. Unlike regular plywood grades, both A and B marine grades are high quality. However, Marine Grade A has fewer defects and knots than Grade B.

So, if you were to use the highest quality grade A marine plywood, it can last up to 25 years.

Can’t I Just Use Regular Plywood For My Boats Floor?

No, regular interior plywood just won’t cut it when it comes to lasting on a boat.

Even carefully sealing it up won’t do the trick. Why? Because while polyester resin is moisture proof it isn’t wholly water resistant.

Even the otherwise very water-resistant RTD plywood isn’t a suitable option for a boat floor.

On the face of it, RTD plywood sounds like it would be perfect for a boat floor since it’s marketed as water-resistant. But the ‘RTD’ label is a little misleading. It only refers to the moisture resistance of the adhesive used in the plywood – not the actual wood itself.

RTD plywood can definitely handle high humidity and damp conditions. But that moisture rating doesn’t tell you anything about the strength those wood layers.

Also, RTD is more for high humidity places or temporary water contact rather than continuous water submersion. So while RTD plywood is great for some wet applications, it isn’t suitable for a boat floor.

If you want to learn more about RTD plywood, we have a full post exploring how well it works for roofing applications. Check it out here: Can You Use RTD Plywood For Roof Sheathing?

Side Note: Also, just to quickly add, regular shop-standard plywood is often made with non-waterproof adhesive. Which means this type of cheap plywood will rot away very quickly on a boat.

But, if you stick to marine-grade or exterior-grade plywood for your boat floor, you won’t go too far wrong.

So, To Sum Things Up…

There’s no way around it. If you have a marine-based wood project, then marine-graded plywood is going to make your life a whole lot easier.

Used in a range of waterside constructions, both in and out of the water, its frequently recommended for use in high moisture environments.

Its smooth and void free (so no need to waste time with wood fillers and sanding). And it is incredibly strong for such a relatively lightweight material.

You can make do with exterior plywood too, but be prepared to put in a fair amount of elbow grease to get it up to seafaring-scratch.